Robotic Welding System

SA series robotic welding system features compact size and light weight, offering stable and high-precision performance, which is an ideal choice for arc welding jobs. The robot performs arc welding with highly accurate welding path and short welding cycle time in a stable manner, thus extending lifetime of process tubes and cables. With compact size, the robotic welding system can be deployed flexibly, with which welding jobs can be done in narrow environments. With convenient installation, the industrial robot can be floor-mounted, invert-mounted or wall-mounted in any angle.

Features

1) User friendly

Easy to install and learn;

Easy to maintain and operate.

2) Fast and accurate

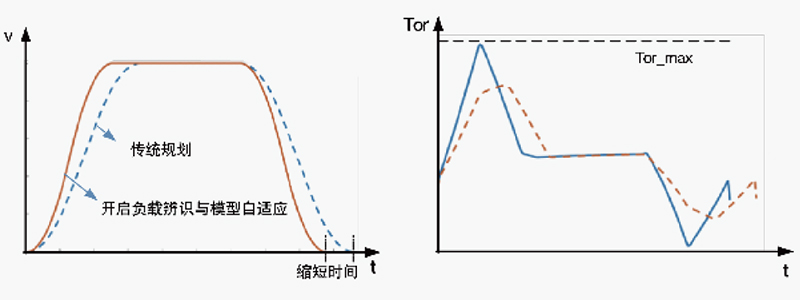

±0.1mm repositioning accuracy, 15% faster in joint motion;

Essential parts are imported;

Self awareness, load identification, vibration control and variable inertia functions.

3) Quality assurance

Our products are:

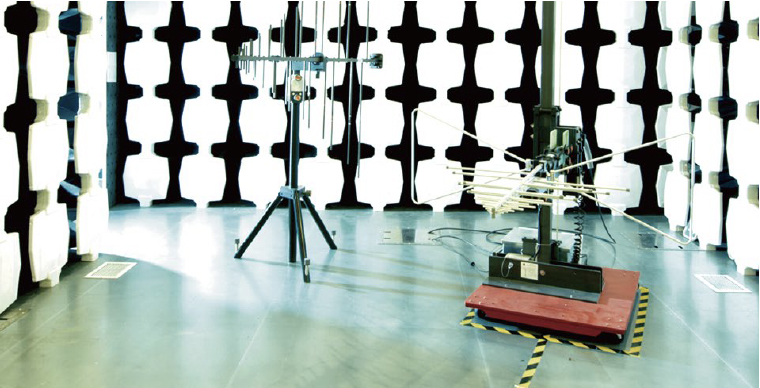

CR certified;

EMC tested.

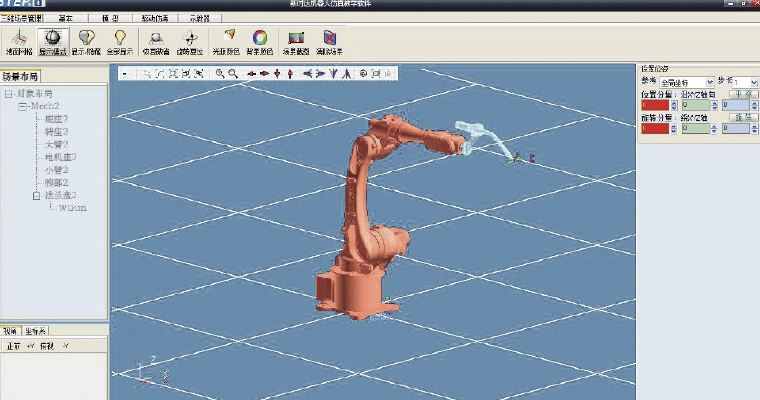

4) Open platform

Self-developed control system and servo drive system by STEP, fast updates;

Codesys platform with customization support.

5) Premium services

Fast-response and all-round services;

Customizable solutions by professional and tech savvy team.

Models

| Model | SA6/1400H | SA6/1400 | SA8/1800 | |

| Max. working radius | 1445mm | 1405mm | 1818mm | |

| Repositioning accuracy | ±0.05mm | ±0.05mm | ±0.05mm | |

| Payload | 6kg | 6kg | 8kg | |

| Degree of freedom | 6 | 6 | 6 | |

| Max. angular velocity of each axis (°/s) | J1 | 220 | 180 | 150 |

| J2 | 220 | 180 | 150 | |

| J3 | 250 | 200 | 160 | |

| J4 | 430 | 450 | 360 | |

| J5 | 400 | 320 | 320 | |

| J6 | 600 | 450 | 360 | |

| Joint motion range (°) | J1 | ±165 | ±165 | ±165 |

| J2 | 155~90 | 155~90 | 155~90 | |

| J3 | Handling: 70~-180 Welding: 70~-90" | 70~200 | 80~190 | |

| J4 | ±170 | ±170 | ±185 | |

| J5 | ±130 | ±120 | ±120 | |

| J6 | Handling: ±360 Welding: ±220" | ±360 | ±360 | |

| Allowable static load torque of wrist | J4 | 11.8Nm | 11.8Nm | 22Nm |

| J5 | 9.8Nm | 9.8Nm | 16.5Nm | |

| J6 | 4.2Nm | 5.9Nm | 6.7Nm | |

| Allowable load inertia of wrist | J4 | 0.6kg·m2 | 0.6kg·m2 | 0.75kg·m2 |

| J5 | 0.25kg·m2 | 0.25kg·m2 | 0.35kg·m2 | |

| J6 | 0.06kg·m2 | 0.06kg·m2 | 0.1kg·m2 | |

| Mounting position | Floor-mounting, invert-mounting, wall-mounting | Floor-mounting, invert-mounting, wall-mounting | Floor-mounting, invert-mounting, wall-mounting | |

Software Package for Arc Welding

1) Essential package: general welding conditions

5 weave bead welding forms are supported;

Canopen/Ethercat supported;

Tack welding and intermittent welding functions;

Welding failure real-time monitoring;

Welding parameter real-time monitoring and online adjusting.

2) High voltage locating package: automatic weld seam identifying and compensating

Up to 200V locating voltage, precision-speed balanced;

Up to 0.25mm locating precision;

Single point locating within 1-2s;

Various locating techniques, 1D/2D/3D/6D included;

Automatic calculation of weld seam status.

3) Arc welding tracking package: external-device-free real time correcting

No need for external devices;

Correcting of up to 17° weld seam deviation;

3mm+ plates supported for welding, tracking function supported with 110A+ current;

Lengthways tracking function to ensure electrode extension;

Self-adaptive tracing algorithm, easy debug and maintenance.

4) Spot laser locating package: multi-purpose spot laser locating algorithm

All types of welding wire locating functions are supported;

Touch free, cutting free;

Edge search function for workpiece locating;

Arbitrary space/direction/curved surface;

Parameterized programming interface available.

5) Additional axis coordination package: external axis coordination based on EtherCat

Up to 2.5KHz servo response rate;

Integrated host system DriveMonitor;

Wide range of additional axis options;

High-precision 4 point calibration for additional axis.

6) Laser tracking package: laser tracking by line-scanning

One-key configuration;

Various weld seam types supported;

Real-time tracking in welding process;

Groove position, shape, width, etc. identifying.

7) Various bus interfaces

Canopen/Ethercat/RS232/RS485/Devicenet/Analog

-

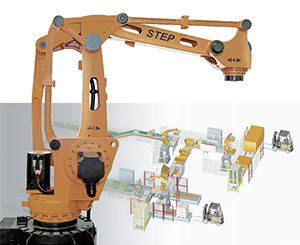

- Robotic Palletizing System

SP series robotic palletizing system is designed with 4-axis, featuring simple structure, and low failure rate. With novel technology and outstanding design, the robot system is granted good user-friendliness, low energy consumption and low area occupation.

-

- Robotic Loading and Unloading System

SR series robotic loading and unloading system features compact structure and stable performance. With high-precision reducer equipped in all joints, the rotating arm is allowed to perform flexible and fast works within limited space.

English

English Español

Español Русский

Русский