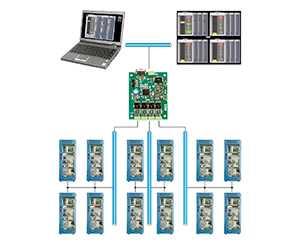

Standard Elevator Group Control System

The elevator group control system is designed based on centralized group control technology. A group controller is used to realize the registration and the allocation of the hall call. CAN-Bus serial communication between the group controller and the elevator's main controller ensures high speed and reliable transmission of massive data. A group controller board mounted with LED indicators, allows us to monitor the communication effectiveness between the group controller and the elevator's main controller, as well as the connection of the input ports. The elevator group control system can manage a maximum of 8 elevators and 48 landings, allowing a wide range of applications.

Working Principles of the Elevator Group Control System

After energized, the main controller of individual elevator will send the hall call button signal to the elevator group control system. The registered hall call signal will then be sent to the landing/indicator board of every floor to acknowledge a landing call and light the call button. If any of the main controllers loses power, the group controller will directly communicate with the call/indicator board, ensuring that the elevator continues to work effectively under group control.

According to the SHORTEST WAITING TIME principle, and considering the distance between the floors, registration status of hall call and car call, by-pass status, reversal running, etc., the elevator group control system performs an effective real allocation of the hall call signal. The system will choose the elevators with the fastest response, thus the transportation capability can be fully excavated and the elevator operation efficiency significantly improved.

If the elevator group control system identifies an elevator which keeps the door open after receiving the allocated hall call signal for long time, the system will cut off that elevator and re-allocate the hall call signals, ensuring the shortest waiting time for the passengers.

In case that the elevator group control system is broken down, under maintenance, or power off, every single elevator will keep simplex running, and automatically return to the group control mode after the group controller is restored.

Main Functions of the Elevator Group Control System

To meet different requirements and enhance the operation efficiency, the elevator group control system may offer multiple functions.

Automatic Homing to Main Floor

To enhance the transportation ability for main floor, when there is no elevator at the main floor, the elevator group control system will allocate the unallocated elevator that will reach the main floor most easily.

Disperse Car Waiting

Disperse car waiting mode starts when all the elevators under the elevator group control system are idle for more than one minute. The system will allocate one elevator which will reach the main floor most easily to the main floor waiting with the door closed, if there is no elevator at the main floor or below. The system will allocate one elevator which will reach the higher level floors most easily to the higher level floors waiting with the door closed, if there are two or more elevators in normal use, and there is no elevator at the main floor or below.

Up Peak Service and Down Peak Service

During the up peak time set manually or by the timer relay, when more than 3 commands are registered in the elevator that is running upwards above the main floor, up peak service function will be started by the elevator group control system. Elevators are allocated to the main floor waiting with door open (2 for 2-3 lift group, 3 for 4-5 lift group, 4 for 6-7 lift group and 8 for 8 lift group). When the up peak time is over, the elevator group control system will resume to normal status.

Similarly, down peak service starts during the down peak time, when the elevators are full-loaded and traveling downwards from the upper floors to the main floor. Elevators are allocated to the highest landing with the same number as the up peak service. When the down peak time is over or no full loading is detected for the elevators going downwards above the main floor for 2 consecutive minutes, the elevator group control system will resume to normal status.

Service Floor Switched Over

The elevator group control system provides two preset service floor schemes. Each scheme designates every elevator to respond to the commands, up calls or down calls on specified floors. Two schemes can be controlled by two switches or two timer relays.

Group Split

A switch for group split is provided in this function. The elevator group control system will split the elevator group into two independent groups according to the setting when the switch is on. And resume to normal status when the switch is off.

Enforced Simplex Mode

A switch for enforced simplex mode is provided on the car operation panel in this function. When this switch is on, the corresponding elevator will run in simplex mode. When the switch is off, the elevator group control system will resume to normal group control status.

Energy Saving Mode

In this function, the elevator group control system will gradually reduce the number of elevators in service until the requirement is reached or there is only one elevator in the group, when the system detects that the number of elevators in service is more than the requirement to meet the minimum service demands. The elevators not in service will be at sleeping mode and the elevator running frequency is reduced accordingly, thus brings energy saving. Similarly, the elevator group control system will increase the elevator number by waking up the elevators in sleeping mode, when the system detects that the number of elevator in service is less than the required number for service.

Emergency Power Operation

This function is selected for the elevators with group control function and the building with emergency power supply. During power failure, the emergency power is switched over and the elevator group control system will allocate the elevators to the main landing in turn with door open, releasing the passengers. To avoid emergency power supply insufficient caused by simultaneous running, the elevator group control system will decide the running order according to the preset parameters.

Our company is a professional elevator group control system manufacturer and supplier in China. At STEP we also provide elevator control cabinet, escalator control system, general vector inverter, elevator inverter, and much more.

- Remote Elevator Monitoring System

This elevator supervising and controlling system supports multi-level authorized management modes set by intelligent computer software. This allows the operator to control and adjust the elevator in the monitoring room. Since this system is designed with real-time fault alarm and intelligent fault information reporting function, the operator will know the fault and its reasons at once when there is something wrong with the elevator. With strong monitoring capacity, this system is able to manage 100 sets of individual elevators at the same time.

- Elevator Destination Dispatch System

a. The up peak mode can be set according to time. You can set each day's initial time and end time for up peak mode within a week. b. The up peak mode is also able to be triggered by a switch. The elevator will enter up peak mode after the up peak service switch is on under any condition. c. Up peak mode will be intelligently identified when all elevators in a group are running and quantity of registered floor call departing from the lobby exceeds the preset value.

English

English Español

Español Русский

Русский