SCARA Robot Controller QC400A

Specifications

| Integrated controller | Axis control | Axis quantity to control | 4 | |

| Position control period | 8K | |||

| Motion/servo control | Arch motion, line interpolation, arc interpolation, continuous trajectory, various types ofacceleration/deacceleration | |||

| Types of coordinates | Joint coordinate, Cartesian coordinate | |||

| Units of positions | Degree and millimetre | |||

| Offline motion control | Complete absolute positioning (no origin required) | |||

| Programming environment | AR | |||

| Data storage | USB-Disk, SD-Card | |||

| Standard IO | IO input | 34point/1.5m | ||

| IO output | 27point/1.5m | |||

| External communication interfaces | RS-232 | 3 | ||

| Ethernet | 1 | |||

| LVDS | 1 | |||

| USB (2.0) | 2 | |||

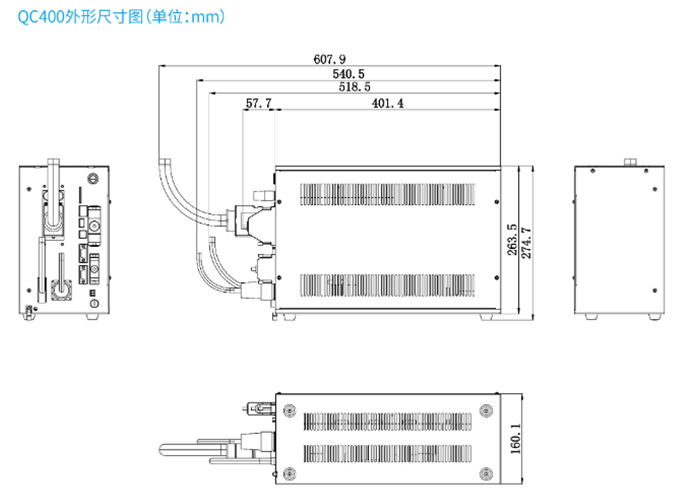

| Basic parameters | Dimension | 400mmx260mmx160mm | ||

| Weight | 10kg | |||

| Power source cable length | 3m | |||

| Heavy duty cable length | 3m | |||

| Power source | AC220V | |||

| Working temperature | 0-40℃ | |||

| Working humidity | Under 90% RH (dew condensation is not allowed) | |||

| Storage temperature | -10-65℃ | |||

QC400 Dimensions (mm):

Features and Functions:

1. Axis quantity to control: 4;

2. Straight path and arc path interpolation;

3. Continuous trajectory controlling, trajectory tracing;

4. Various types of acceleration/deacceleration;

5. Convenient operation and easy programming;

6. Driving function and controlling function integrated together, wire-saving, room-saving and cost-saving.

-

- SCARA Robot Controller QC410B

QC410B SCARA robot controller is equipped with our up-to-date technology, able for teach-pendant-free controlling. The controller features up to 30% less weight, over 50% better chip performance and more stable hardware design that the old types.

-

- Robotic Welding System

SA series robotic welding system features compact size and light weight, offering stable and high-precision performance, which is an ideal choice for arc welding jobs. The robot performs arc welding with highly accurate welding path and short welding cycle time ...

English

English Español

Español Русский

Русский