SCARA Robot Controller QC410B

QC410B SCARA robot controller is equipped with our up-to-date technology, able for teach-pendant-free controlling. The controller features up to 30% less weight, over 50% better chip performance and more stable hardware design that the old types. Robots applying the controller perform faster speed, more stable movement and more accurate trajectory. Besides, the QC410B controller equips our novel high-precision vision-based calibration and fast dynamic grasp techniques.

Specifications

| Model | QC410 | External data storage | USB-Disk | ||

| Available robots | AR/GR/FR SCARA Robots | Emergency stop | By hardware | ||

| Programming environment | Programming language | AR | Standard IO | IO input | 34point |

| Multi-thread function | Up to 10 threads | IO output | 27point | ||

| Max. single-thread point quantity | 3000 | Basic parameters | Dimension | 345mm*234mm(terminal included)*150mm | |

| Max. program capacity | 1GB | Weight | 7.45kg | ||

| Max. step number of program | 10000 | Power source cable length | 1.5m | ||

| External communication interfaces | EtherCAT | 1 | Power source | Single phase AC200V-AC240V, 50Hz/60Hz | |

| Ethernet | 3 | Max. power capacity | 3000VA | ||

| RS-485 | 1 | Working temperature | -5-50℃ | ||

| RS-232 | 2 | Working humidity | Under 90% RH (dew condensation is not allowed) | ||

| USB(2.0) | 1 | Storage temperature | -30-70℃ | ||

| Axis control | Axis quantity to control | 4 | Handheld teach pendent | ADT-RPB07 | |

| Position control period | 8K | PC software | ARStudio | ||

| Motion trajectory control | Point to point motion, arch motion, straight line trajectory, arc trajectory, spline curve trajectory, smooth transition, various types of acceleration/deacceleration | ||||

| Types of coordinates | Joint coordinate, world coordinate, tool coordinate, user coordinate | ||||

| Units of positions | Degree and millimetre | ||||

| Acceleration/deacceleration | Manual set by parameters/automatic set according to load weight and inertia | ||||

| Offline motion control | Complete absolute positioning (no origin required) | ||||

-

- Robotic Welding System

SA series robotic welding system features compact size and light weight, offering stable and high-precision performance, which is an ideal choice for arc welding jobs. The robot performs arc welding with highly accurate welding path and short welding cycle time ...

-

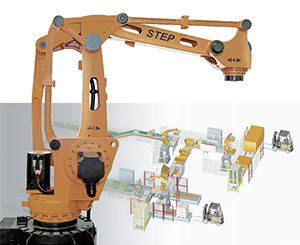

- Robotic Palletizing System

SP series robotic palletizing system is designed with 4-axis, featuring simple structure, and low failure rate. With novel technology and outstanding design, the robot system is granted good user-friendliness, low energy consumption and low area occupation.

English

English Español

Español Русский

Русский